Introduction to Cement Sheets

Cement sheets, also known as fiber cement boards, are strong building materials. They are made by mixing cement with tiny fibers from plants, called cellulose fibers. This mix creates flat boards that are tough and last a long time.

Definition and Composition

Fiber cement boards are made from three main parts:

- Cement: This holds everything together and makes the board strong.

- Cellulose Fibers: These plant fibers help make the board flexible and less likely to crack.

- Silica: This adds extra strength and durability to the board.

Common Applications in Construction

Fiber cement boards are used in many building projects because they are strong and can resist weather, fire, and pests. Here are some common uses:

| Application Area | Description |

|---|---|

| External Cladding | Used on the outside of buildings to protect against weather and give a nice appearance. |

| Roofing | Used as roofing materials due to their strength and durability. |

| Tile Backer Boards | Placed behind tiles in bathrooms and kitchens to prevent water damage. |

| Partition Walls | Used to create internal walls that are strong and fire-resistant. |

| Ceilings and Floors | Installed in ceilings and floors for added strength and fire resistance. |

These boards are popular in construction because they are strong, last a long time, and can be used in many ways. However, over time, they can develop cement sheet marks, which are stains or blemishes that may affect their appearance. Understanding how to prevent and treat cement sheet marks is important for maintaining the look and durability of these materials.

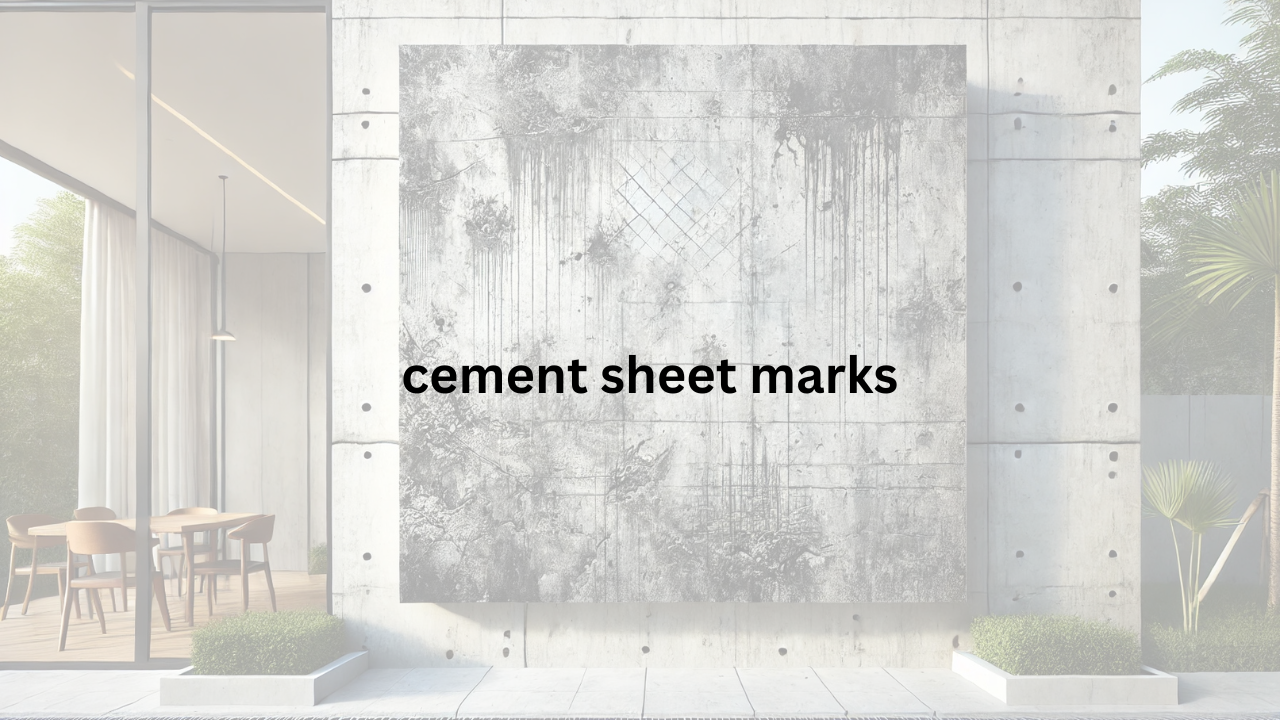

Identifying Common Marks on Cement Sheets

Cement sheets, also known as fiber cement boards, are strong and durable materials used in building homes and other structures. However, over time, they can develop marks and stains that may affect their appearance. These blemishes, often referred to as “cement sheet marks,” can result from various factors.

Types of Marks and Stains

Understanding the different types of marks that can appear on cement sheets is essential for proper maintenance.

| Type of Mark | Description |

|---|---|

| Water Stains | Caused by prolonged exposure to moisture, leading to discoloration. When water continuously contacts the cement sheets, it can penetrate the material, causing dark spots or streaks. |

| Mold and Mildew | Growth resulting from damp conditions. In humid or shaded areas, mold and mildew can develop on the surface, appearing as black or green patches. |

| Efflorescence | White, powdery deposits formed by salt migration to the surface. This occurs when water-soluble salts within the cement migrate to the surface and crystallize as the water evaporates. |

| Scuff Marks and Scratches | Physical damage from handling or environmental factors. These can occur during installation or from impacts, leading to visible lines or abrasions on the surface. |

Regular inspection and maintenance can help identify and address these cement sheet marks early, preserving the appearance and longevity of your cement sheets.

Causes of Cement Sheet Marks

Cement sheets, also known as fiber cement boards, are popular in construction due to their durability. However, they can develop marks and stains over time. Understanding the causes of these “cement sheet marks” is essential for prevention and maintenance.

Environmental Factors

| Cause | Description |

|---|---|

| Moisture Exposure | Rain, humidity, and condensation can lead to water stains and mold growth. When cement sheets are exposed to excessive moisture, they may develop dark spots or streaks due to water penetration. |

| UV Radiation | Prolonged exposure to sunlight can cause fading and degradation over time. Ultraviolet rays can break down the surface of cement sheets, leading to discoloration and a weakened structure. |

Installation and Handling Issues

| Cause | Description |

|---|---|

| Improper Sealing | Lack of adequate sealing allows moisture penetration. Without proper sealing, water can seep into the cement sheets, causing stains and promoting mold growth. |

| Physical Damage | Scratches and scuffs from mishandling during installation. Handling errors can lead to surface abrasions, making the sheets more susceptible to environmental damage. |

Chemical Reactions

| Cause | Description |

|---|---|

| Alkaline Reactions | Reactions between cement components and environmental chemicals. Certain chemicals can react with the alkaline nature of cement, leading to discoloration and surface damage. |

Understanding these causes is crucial for preventing and addressing cement sheet marks, ensuring the longevity and appearance of cement sheets in construction.

Preventive Measures to Avoid Cement Sheet Marks

Cement sheets, also known as fiber cement boards, are durable materials used in construction. To keep them looking good and free from marks, it’s important to follow certain steps during installation and maintenance.

Proper Installation Techniques

| Measure | Description |

|---|---|

| Sealing and Waterproofing | Applying appropriate sealants to prevent moisture ingress. Sealing the surface helps keep water out, reducing the chance of stains and mold. |

| Correct Fastening Methods | Using recommended tools and techniques to minimize damage. Proper installation prevents scratches and scuffs that can occur from mishandling. |

Regular Maintenance Practices

| Measure | Description |

|---|---|

| Cleaning | Routine cleaning to remove dirt and prevent mold growth. Regular washing keeps the surface clean and reduces the risk of mold. |

| Inspections | Periodic checks for early detection of issues. Regular inspections help spot problems early, allowing for timely repairs. |

Remedies for Existing Cement Sheet Marks

Cement sheets, also known as fiber cement boards, are durable materials used in construction. Over time, they may develop marks or stains. Addressing these “cement sheet marks” promptly can restore their appearance and extend their lifespan.

Cleaning Solutions

| Solution | Description |

|---|---|

| Mild Detergents | For general cleaning, mix mild dish soap with water. This solution effectively removes dirt and surface stains without harming the material. |

| Specialized Cleaners | For specific issues like mold or mildew, use cleaners designed for fiber cement siding, such as Jomax® or Mold Armor®. These products target stubborn stains and biological growths. |

Repair Techniques

| Technique | Description |

|---|---|

| Surface Sanding | Gently sand the affected area to remove superficial marks and scratches. Use fine-grit sandpaper to avoid damaging the surface. |

| Patching Compounds | For deeper gouges or damaged areas, apply a cementitious patching compound. This filler restores the surface and prepares it for finishing. |

| Repainting and Sealing | After cleaning or repairs, apply a fresh coat of paint or sealant. This step enhances appearance and provides protection against future stains. |

Case Studies and Examples of Cement Sheet Marks

Cement sheets, also known as fiber cement boards, are widely used in construction for their durability and versatility. However, they can develop marks and issues over time. Understanding real-world problems and their solutions can help in maintaining these materials effectively.

Common Issues Encountered

| Issue | Description |

|---|---|

| Moisture Absorption | Fiber cement siding can absorb moisture if not properly installed or maintained, leading to swelling, cracking, and mold growth. |

| Installation Challenges | The heavy and brittle nature of fiber cement boards makes installation difficult, often resulting in improper fastening or alignment, which can cause future problems. |

| Maintenance Requirements | Regular maintenance, including painting and caulking, is necessary to prevent deterioration and staining of fiber cement siding. |

Effective Solutions Implemented

| Solution | Description |

|---|---|

| Proper Sealing | Applying appropriate sealants and ensuring all gaps are caulked can prevent moisture ingress, reducing the risk of swelling and mold. |

| Professional Installation | Hiring experienced professionals for installation ensures correct handling and fastening of fiber cement boards, minimizing potential issues. |

| Regular Maintenance | Implementing a routine maintenance schedule, including cleaning and repainting, helps in preserving the appearance and integrity of fiber cement siding. |

By examining these common issues and their solutions, homeowners and builders can take proactive measures to prevent and address cement sheet marks, ensuring the longevity and aesthetic appeal of their structures.

Conclusion

Understanding the causes of cemen sheet marks and implementing preventive measures can significantly reduce their occurrence. Regular maintenance is essential to preserve the aesthetic and functional qualities of cement sheets.

Summary of Key Points

| Key Point | Description |

|---|---|

| Understanding Causes | Identifying factors such as moisture exposure, improper sealing, and physical damage that lead to cemen sheet marks. |

| Implementing Preventive Measures | Applying proper installation techniques, sealing, and waterproofing to prevent marks. |

| Regular Maintenance | Conducting routine cleaning and inspections to maintain the appearance and integrity of cement sheets. |